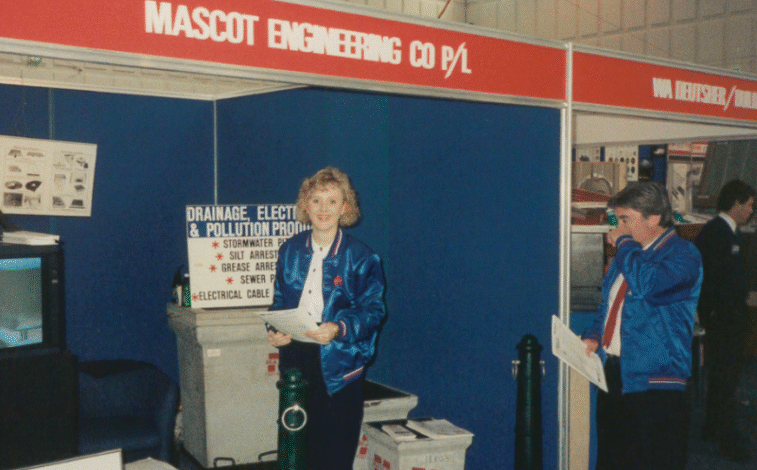

40 Years of Mascot GRC

An Australian Innovation Story

This year, Mascot Engineering proudly celebrates 40 years of Mascot GRC — our unique Glass Reinforced Concrete that has changed the way Australia approaches drainage, stormwater, and underground cable jointing systems. What began as an idea to make infrastructure lighter, stronger, and easier to handle has grown into a true Australian success story of innovation, craftsmanship, and commitment to local manufacturing.

How It All Began

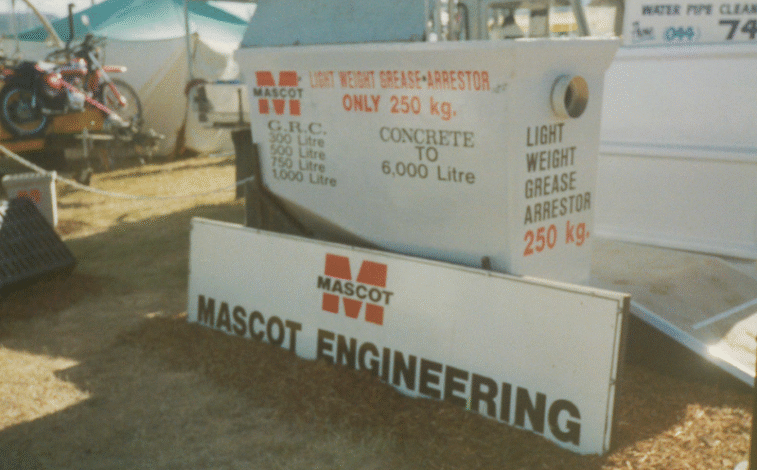

In the early 1980s, Bryan Taylor had a vision… to create a lightweight concrete pit that was tough enough for Australian conditions, yet far easier to transport and install than traditional steel-reinforced concrete. With global GRC expert and engineer Charles Rickard, Mascot Engineering developed the Mascot GRC Pit — the first of its kind in the world.

The result was a game-changer. Strong, lightweight, and long-lasting, Mascot GRC quickly became the preferred alternative for stormwater and drainage applications. Before long, it also found a home in cable jointing infrastructure, giving the market a reliable, Australian-made alternative to imported polymer concrete and other lightweight products.

Engineered for Strength, Safety, and Performance

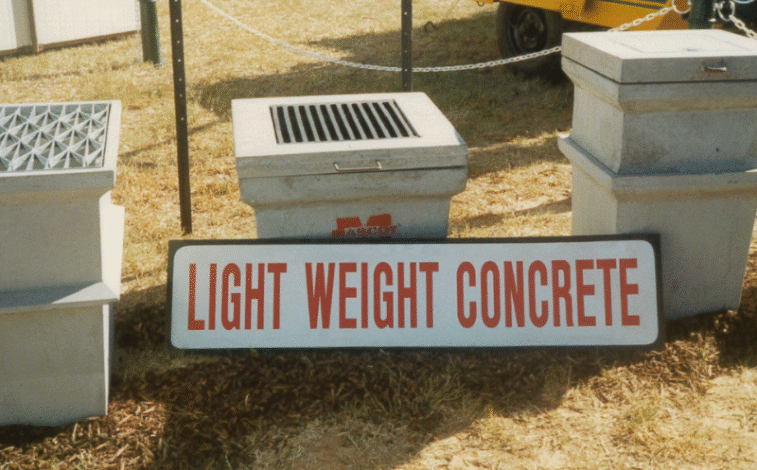

The result was a pit that offered all the strength and durability of traditional steel reinforced concrete – without the weight. Its lightweight composition makes handling and installation faster, easier and safer on site.

Engineered with precision, Mascot GRC achieves an impressive compressive strength of 80 MPa and flexural strength of 24 MPa. It’s chemically resistant, non-corrosive, and completely steel-free, making it ideal for electrical applications and long-term reliability in tough Australian conditions.

Proving once and for all that a pit, is not just a pit.

Built for Australian Conditions

Every Mascot GRC pit is made in Sydney and engineered specifically for the harsh Australian environment — from coastal regions to inland extremes. Designed for long service life and easy handling, Mascot GRC products are fully compatible with AS3996-compliant covers and grates, ensuring strength, safety, and performance in every installation.

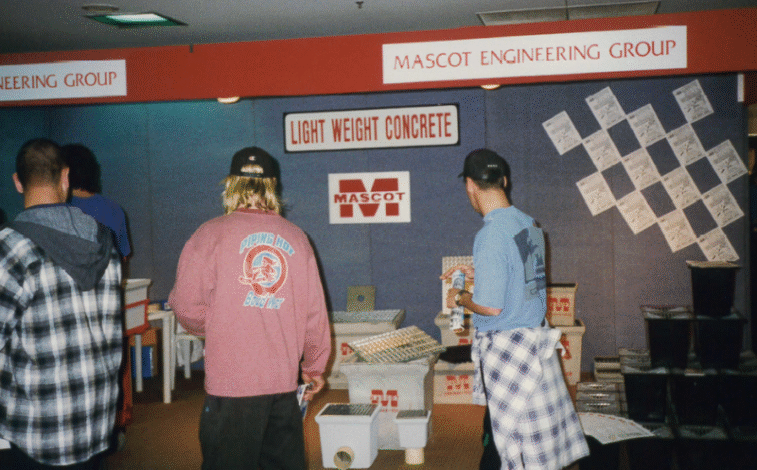

A Proven Performer — At Scale

Today, Mascot Engineering produces more than 2.2 million kilograms of GRC each year — an impressive figure when you consider that Mascot GRC weighs roughly one-tenth of traditional concrete.

That equates to over 27,000 Mascot GRC pits and risers supplied annually, supporting more than 100 projects every week across Australia. It’s a testament to the trust our customers place in Mascot GRC and the consistency, quality, and dependability that have defined our products for four decades.

Proudly Australian Made

As a third-generation Australian-owned company, Mascot Engineering has always believed in doing things locally. Manufacturing in Sydney gives us complete control over quality and consistency while supporting Australian jobs and industry. When you choose Mascot, you’re supporting local innovation, reliability, and the next generation of Australian manufacturing.

A Greener Future

Mascot Engineering is committed to building a more sustainable future. Our Sydney facility uses solar power, water recycling, and efficient batching systems to reduce energy use and waste. With a lighter environmental footprint than traditional concrete, Mascot GRC proves that strength and sustainability can work hand in hand.

The Next Chapter — World-First GRC Plant in Sydney, Delivering More for Customers

As we celebrate this milestone, we’re also investing in the future. This year, Mascot Engineering commissioned a world-first, custom-built GRC batching plant at our Sydney headquarters.

This state-of-the-art facility brings next-level precision, consistency, and efficiency to every product we make — but more importantly, it means better outcomes for our customers. With increased capacity, we can now maintain larger stock holdings and faster turnaround times, ensuring you get the products you need… when you need them.

It’s another example of Mascot Engineering’s commitment to Australian manufacturing, combining innovation, dependability, and customer-first thinking — all built right here in Sydney for the Australian building, plumbing, electrical and infrastructure industries.

For four decades, Mascot GRC has set the benchmark for quality, reliability, and performance in precast infrastructure. As we look ahead, we remain true to the same values that started it all — innovation, integrity, and Australian-made excellence.