Defence

Defence projects demand product solutions that are specifically designed, engineered, and manufactured to suit an environment subject to extremely heavy traffic loads and often unique and isolated environments.

Whether it be Navy, Army or Air Forces, with over 100 years manufacturing in Australia, we are the experts in the manufacture and supply of in-ground, compliant products designed for and trusted by Australian Defence projects.

Whilst our products are installed in new defence bases, the majority of our recent projects supplied have been upgrades or extensions. Developments have included weapons storage and training facilities, runway and hangar upgrades (including viking systems), wash bays, CCTV and communications infrastructure, temporary and permanent housing, fuel valves and fuel line upgrades and extensions, shipyards, dry docks and maintenance facilities.

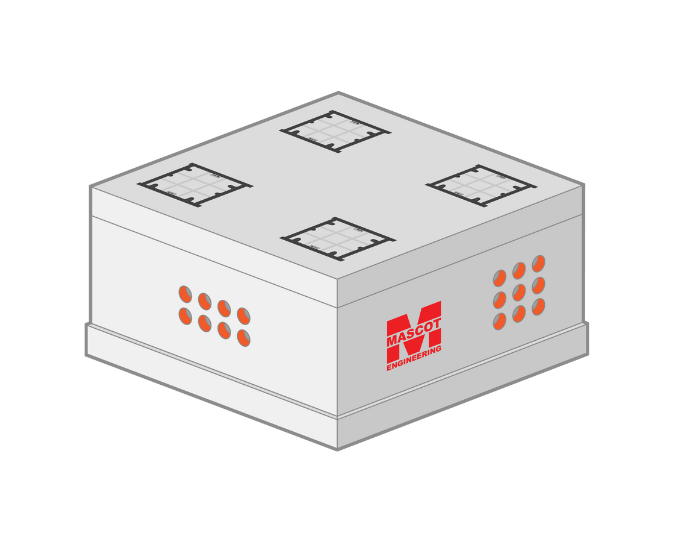

The technical team at Mascot Engineering regularly design custom solutions to meet the specific needs of various projects across Australia and the world. If your application requires a custom designed product, our experienced team are on hand to work with you to provide the right solution that’s compliant and built to last.

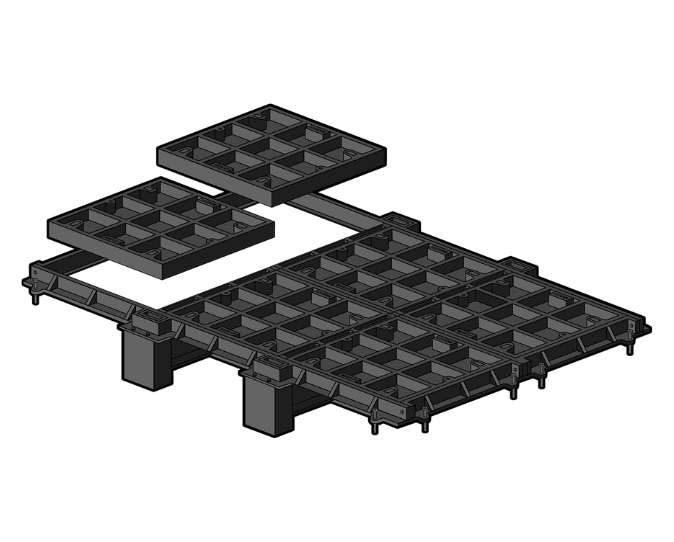

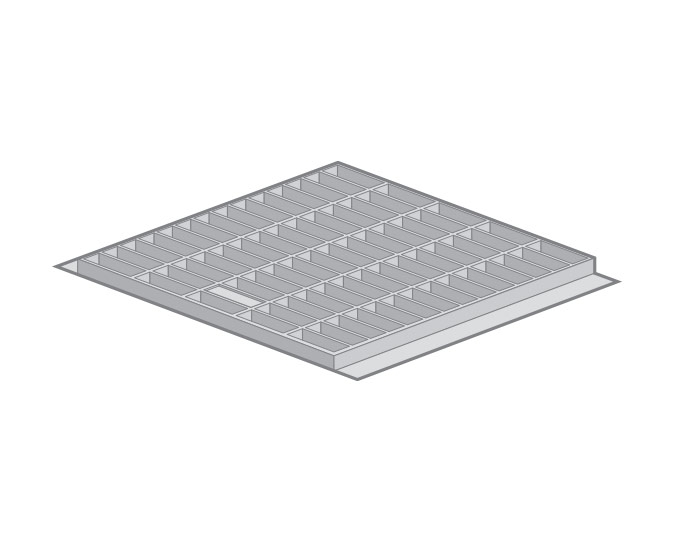

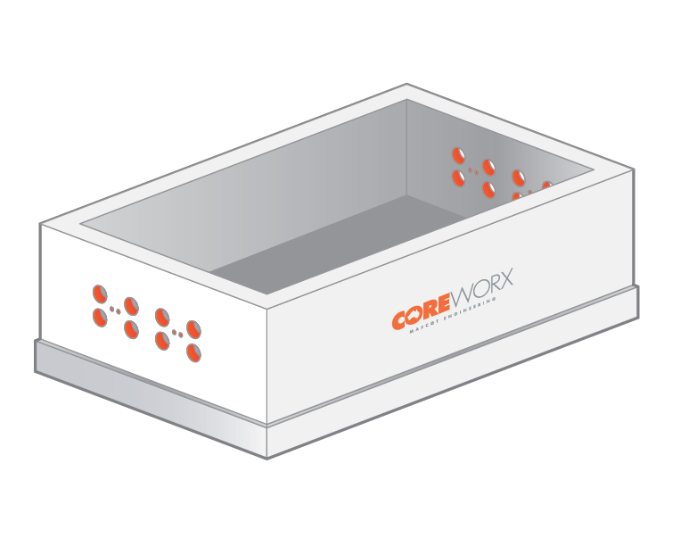

Not only do we have a huge range of pits and enclosures, with our local in-house capabilities to assemble multipart covers (gas and air tight inspection covers) with fixed or removable beams we’re one of the most experienced manufacturers of custom access covers in Australia. And of course, our ductile iron trench grates and frames in Class D, Class E and Class G can be found installed in defence projects across Australia.

Mascot’s range of products meet all relevant Australian and industry Standards and are approved by relevant authorities for use Australia wide… though most importantly, our products are manufactured to the exacting standards Defence requires. Our proven track record underlines this.

Some of the Defence projects we’ve supplied

HMAS Penguin, Sydney, NSW

Garden Island Royal Australian Navy Base, NSW

RAAF Base Pearce, WA

HMAS Harman, ACT

HMAS Williamtown, NSW

RAAF Base East Sale VIC

Holsworthy Army Barracks Defence Transport & Logistics Facility Upgrade, NSW

Counter Terrorism Centre

Army Aviation Centre Oakey, QLD

Department of Defence Housing Projects

HMAS Albatross HM-60R Facility, NSW

Randwick Barracks Building 310, NSW

Centre for National Resilience, Pinkenba QLD

RAAF Richmond, NSW

Swan Island Army Base – Queenscliffe, VIC

RAFF Glenbrook, NSW

HMAS Watson Building 328, NSW

HMAS Bandiana, VIC

More projects can be found here.

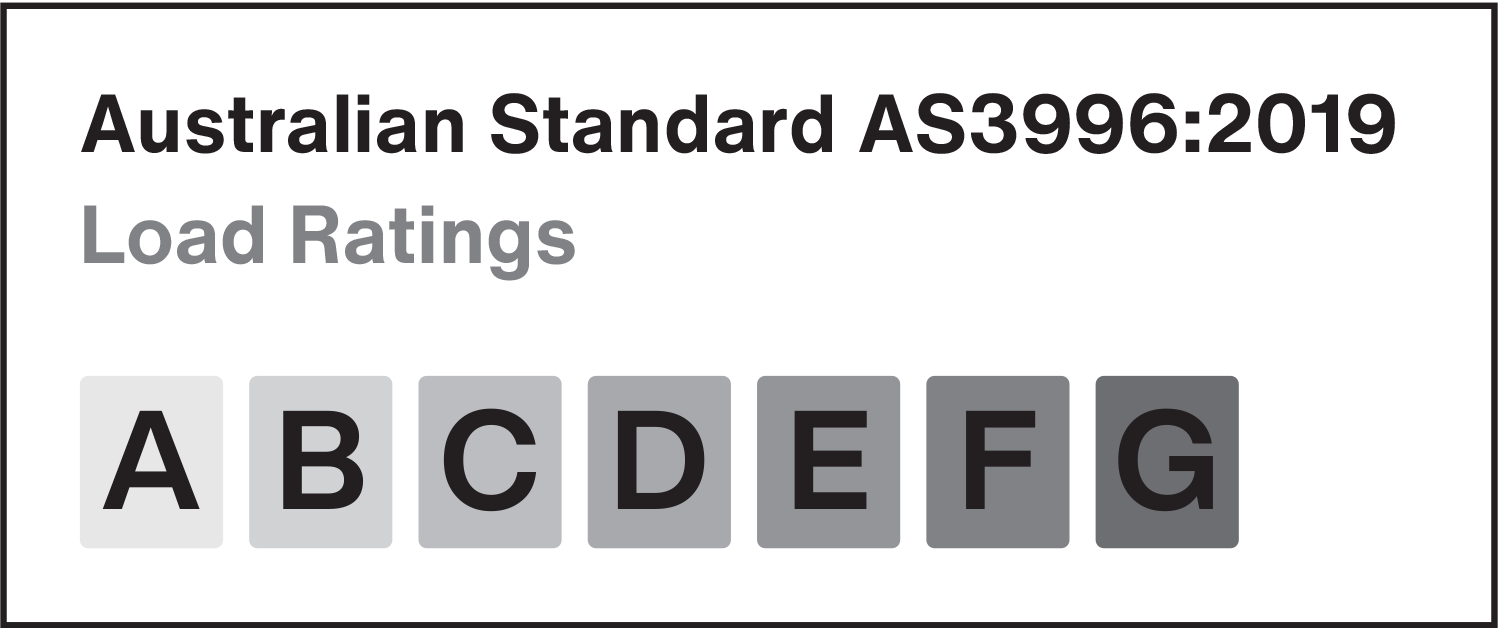

Mascot Engineering’s range of products are manufactured to comply with Australian Standards AS396:2019, and are available in Load Ratings A to G.

Defence

Case Studies

Heavy Vehicle Wash Bay

Sydney Airport Fuel Pit

HMAS Watson