Designed for Safety & Efficiency: Mascot’s Patented Levelling Bolt System

At Mascot Engineering, we don’t just supply products… we solve problems on site.

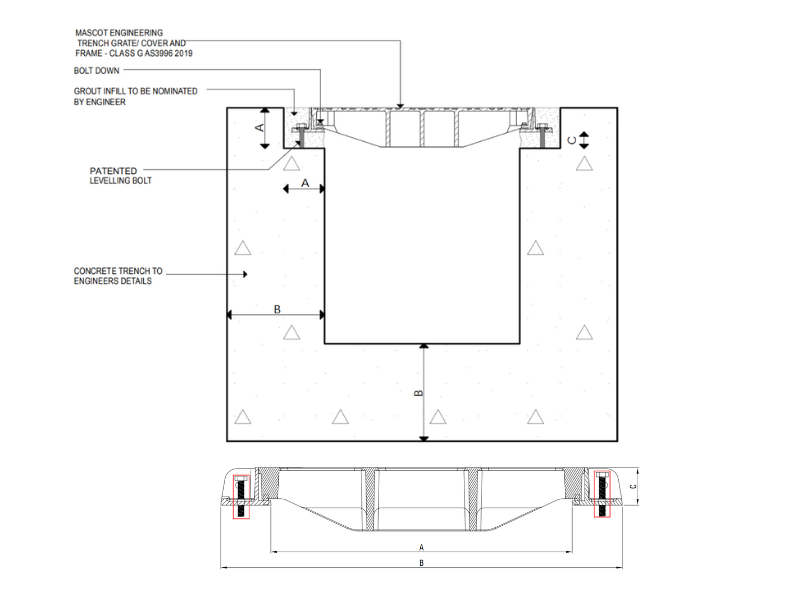

During installations of trench grates and access covers—especially our heavy-duty Class G (AS3996:2019) and F900 (EN124) rated systems—we identified a consistent challenge contractors faced: ensuring the top of the grate or cover sits flush with the finished surface. Whether the install involves a pre-formed rebate or a single-pour construction, achieving correct levels can be time-consuming and hazardous.

Installers often resort to manual packing under the frame—introducing OH&S risks, increasing labour time, and potentially compromising structural performance with the frame of the product not being completely supported, risking future failure.

That’s why we developed and patented our Levelling Bolt System, now protected under an Australian Innovation Patent (Patent No. 2020102484).

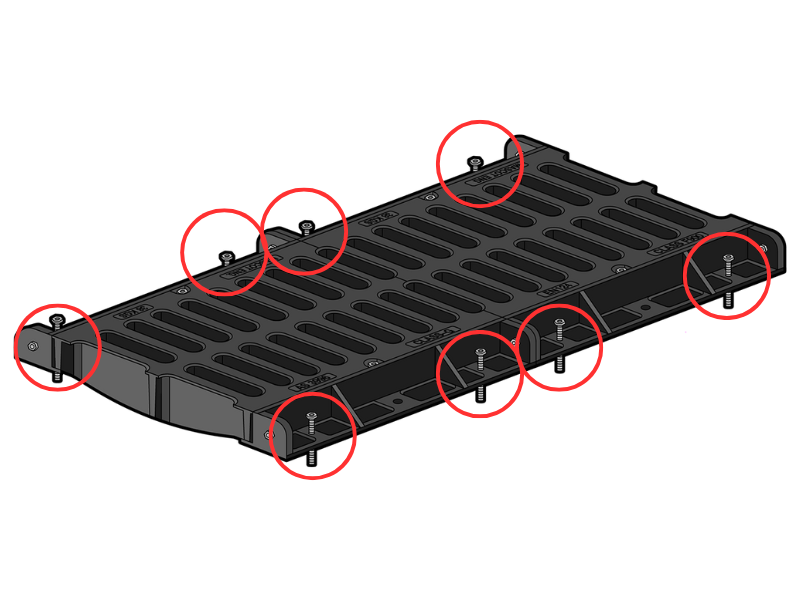

This smart solution allows installers to adjust the frame height quickly, safely and precisely using a bolt hole integrated into the seat of the frame. The system eliminates the need to position hands or packers underneath, dramatically reducing risk while improving installation efficiency.

Every site presents its own set of variables—and this system is designed to adapt, helping ensure each frame is fully supported to meet its rated load. The result: safer, faster, and more reliable installations allowing for the product to perform as intended.

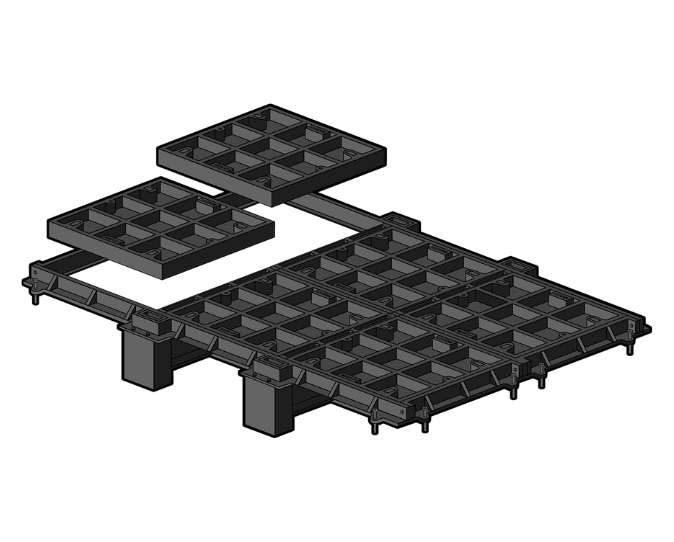

Now standard across most Mascot ductile iron trench grates and access covers (including trench runs and multiparts), particularly in our Class G and F900 range, this patented innovation demonstrates our ongoing commitment to practical, performance-driven product solutions.