Installation Instructions – Trade Waste

Given the large range of trade waste products, there are various standard installation instructions for our products.

All trade waste products are delivered to site with the relevant details attached to the inlet pipe. It’s important to note that all information regarding installation is ‘typical’ and is to be used as a guide only – it does not take into account site specific limitations or requirements. Installers must observe the relevant codes of practice and standards legislated. This product is to be installed by an experienced and licenced plumber and the product should not be put into use until installation is complete (backfilled etc.).

Installers should refer to relevant Plumbing and Drainage Regulations, or codes of practice in the area of installation.

We recommend contractors contact ‘Dial Before You Dig’ on 1100 or at www.1100.com.au .

Site conditions may require additional reinforcement or a change to these details that may need to be provided by an engineer.

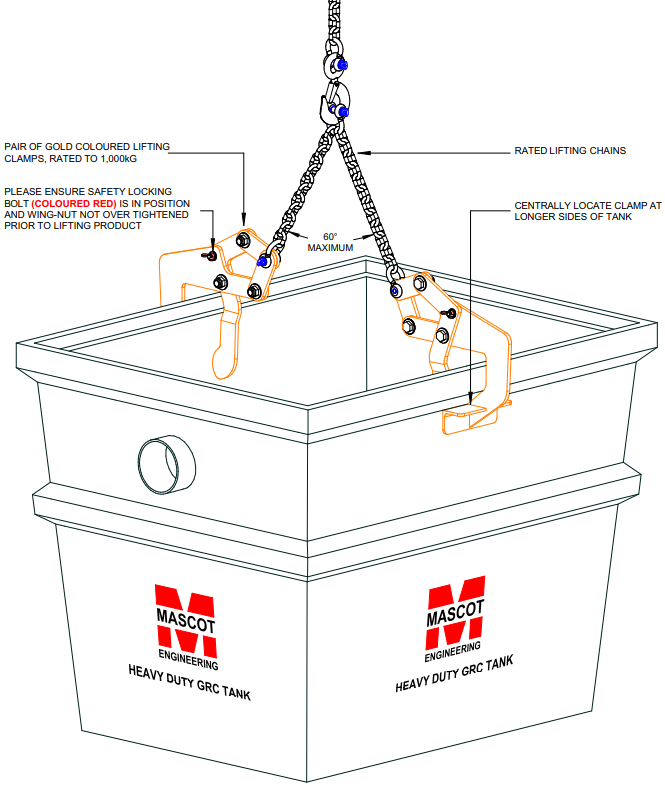

- Refer to the ‘Lifting Instructions’ prior to moving the product on site – see below/attached.

- Prior to installation, determine the exact location of the inlet and outlet.

- All products are designed to be installed level.

- If installation is above ground, the product must be complete with a Mascot Engineering manufactured stand (additional cost) and suitably attached to the finished floor (dyna-bolts or similar – supplied by others).

- The excavation shall be done to the necessary depth (allowing for thickness of cover).

- If any soft or unsuitable material is found it shall be removed and all the bearing surfaces under the tank shall be compacted and levelled.

- A layer of compacted granular material shall be installed under the tank to ensure support that will not yield or deflect when the product is in service. Clean, granular backfill to be used to appropriate level and compacted in layers of no more than 300mm and without machine to ground level.

- The product is to be bedded on a 50mm layer of stabilised sand with backfill of same to the top of the lower external rib (flat bottom) or to a horizontal level 200mm above the higher point of the sloping base (boat-shaped).

- All external connections to and from the product are to completed to the relevant Australian Standard and codes of practice.

- Extension risers and covers to be sealed with Mascot Engineering Pipe Joining Epoxy or an approved epoxy compound to form a watertight joint.

- Compaction should not take place without the cover being in place (installed/attached).

- For deep installations, we recommend the 4:1 sand/cement backfill be increased so that no more than 1800mm below the surface is without the backfill (including cover thickness).

- Where the water level is greater than 1000mm below the finished surface level a galvanised internal work platform as well as step irons should be fitted.

- If a solid top pedestrian load cover is being used, ensure transit bolts are removed before fitting.

Installation in Rock:

To ensure your product doesn’t ‘float’, if your installation is in rock, we recommend seeking instructions from your site engineer and that you backfill with a stabilised sand/cement mix from the base up to the top of the rock as well as no less than 1800mm from the finished surface level. For example, if your installation is 3200mm deep, it is recommended that the backfill is to a minimum of the first 1400mm unless the rock is deeper in which case you will continue to the top of the rock. Please refer to your engineer for specific details.

Recommended Inspection /Maintenance Program

Removal and replacement of access covers:

All covers are to be removed with Mascot Engineering lifting keys. Covers must be returned to their exact position, first checking that the rebate seat is clean and that a heavy duty grease is applied to all edge surfaces. For more information on direction of covers, refer to our Access Covers installation instructions.

Tank Pump Out:

The frequency will be determined by your local trade waste authority and should only be done by a registered waste transporter. The sides of the tank must be cleaned and scraped down using a rubber or plastic edge scraper to remove any build up and not damage the surface coating. A visual inspection of the internal coating should be done and rectified if needed.

Yearly Requirement:

Given the acidic nature of the contents, it is required that the above pump out and cleaning is done annually to ensure the ongoing efficiency of the product. A visual inspection of the internal coating must be completed and rectified if damaged.

Internal Epoxy Coating:

All trade waste products are coated internally with epoxy to protect the product from an acid attack. Given Mascot Engineering’s products are manufactured from Glass Reinforced Concrete (GRC), there is no steel present, so the possibility of traditional concrete cancer is removed entirely. If the unit is not maintained and cleaned regularly, it may need re-coating. If re-coating is required, the product must be dry for at least 24 hours, then cleaned. Only Mascot Engineering’s tar epoxy based coating should be used and allowed to dry (24 hours) before the unit is used.

Guarantee:

If your product fails as a result of poor workmanship within 12 months of purchase, Mascot Engineering will provide a replacement product at no charge.

Prior to lifting, please make yourself aware of the local legislation and codes as well as any specific requirements on your site.

CLICK HERE FOR FULL INSTRUCTIONS ON HOW TO SAFELY LIFT MASCOT ENGINEERING GRC TANKS