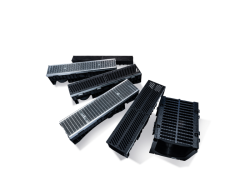

Trench Grating

With a huge range of trench grates and frames as well as surface drainage channel systems, Mascot Engineering can cater for all your grating needs.

Manufactured to suit all load ratings (AS3996) from Class A to Class G, below you will find links to our standard stock products. If you can’t find what you’re looking for here or need a custom solution, contact us and we can manufacture to your specifications.

Trench Grating

With a huge range of trench grates and frames as well as surface drainage channel systems, Mascot Engineering can cater for all your grating needs. Manufactured to suit all load ratings (AS3996) from Class A to Class G, we offer a range of standard stock products or custom solutions can be manufactured to suit your projects needs.

Overview of Trench Grating

Trench grating is a vital surface drainage system that collects and directs water away from a site, preventing excess water build-up and reducing the risk of flooding. Each grate is installed into a frame, with the system designed to direct water through channels and keep pedestrians and vehicles safe.

These products are an essential component of safety, erosion minimisation, and long-term asset protection. Trench Grating is used in numerous applications including; residential driveways, carparks, shopping centres, pedestrian paths, industrial facilities, heavy-duty loading docks, and streetscape projects requiring safe and durable surface drainage solutions.

Mascot Engineering’s trench grates are manufactured in line with Australian Standards, and in a multitude of sizes and classes to fulfil project requirements for compliance, performance, and quality.

Trench Grating Types and Specifications

Material Options

Mascot Engineering offers a full product range of trench grates produced from superior materials to match the requirements of different projects.

- Galvanised Mild Steel: GMS grates are a great economical choice for general projects as it provides superior corrosion resistance and performs well in applications requiring a load rating to Class D.

- Ductile iron: Ductile cast iron delivers maximum strength for heavy-use applications in highways, loading docks or industrial sites. Cast iron trench grating systems are built for the demanding needs of infrastructure and can be used in applications requiring a load rating to Class G.

- Stainless Steel: Mascot’s range of stainless steel trench grating can be customised to suit your particular project. Stainless is suited to both inside applications such as shower grates and outside applications such as stormwater management, and is available as either 304 grade or 316 grade for marine environments.

Safety and Design Features

Heelproof options

Mascot’s range of heelproof trench grating options are manufactured with 10mm openings to reduce the risk of high heels, canes, mobility aids or bicycle tires becoming lodged.

Slip-resistance surfaces

Depending on the application environment, Mascot can provide slip resistant trench grates that can be rated to P5 as per AS4586 for slip resistance, reducing the risk of slipping. These grates are often chosen for pedestrian areas and environments such as kitchens or hospitals where there is a risk to falling.

Non-rocking

Mascot Engineering’s trench grating products are designed to sit flush with the surface. This design feature ensures a “non-rocking” fit so that the grate does not move under traffic. Additionally, bolt-down features help to secure the grate in place so it cannot be dislodged or become a trip hazard.

Load Capacities

- All trench grating is designed and manufactured to be compliant to the load ratings as designated in AS3996:2019.

- Class A: Suitable for residential driveways and pathways.

- Class B: Designed for carparks and light vehicle traffic.

- Class D: Heavy-duty option for industrial sites and loading docks.

- Class G: Suitable for use under heavy loads that are often required in infrastructure projects such as airports and ports.

For more information on AS3996:2019, click here.

Dimensions and Options

Mascot’s trench grates and frames are available in a range of standard sizes, however, we can custom manufacture suit the needs of your project.

Standar stock item dimensions include:

- Widths: Available in 100 mm, 150 mm, 200 mm and 250 mm internal options.

- Standard lengths: Grates supplied in 1000 mm sections, with frames in 2000 mm lengths.

- Depths: Designed to suit surface drainage applications across residential, commercial and industrial sites.

Compliance and Certification

All trench grating products are manufactured to AS3996:2019 load ratings and produced using ISO-certified processes, providing a guarantee of consistency, quality and reliability. They meet local council compliance and industry expectations, providing durable, corrosion-resistant solutions that can be designed for use in diverse environments. The combination of compliance and solid performance provides the necessary assurance for Mascot’s trench grates and grates to suit drainage pits to be used reliably on projects nationwide.

Product Comparisons and Options

Material Comparisons

Selecting the right trench grating means comparing material performance, durability, and suitability for each project.

- Galvanised Mild Steel Grating: Strong and dependable for typical applications. GMS grates are the most popular option that suits a wide variety of applications requiring a Class B or Class D load rating.

- Cast iron: Durable and generally used for industrial projects, highways, and loading docks where the utmost strength is required.

- Stainless steel: Ideal for projects in coastal environments (316 marine grade stainless steel grating) or hygienic applications, providing long-term corrosion-resistant functionality with minimal maintenance.

Suitability by Environment

Trench grating must be specified according to the environment and load class to ensure safety, compliance and long-term performance.

- Coastal projects: Stainless steel grates are usually the best option for durability and corrosion resistance in harsh environments.

- Residential sites: Class A is suitable for pedestrian areas, and Class B trench gratings are best suited for driveways, carparks and light vehicle areas.

- Industrial facilities and loading docks: Class D or higher trench grating is required to withstand heavy-load traffic and constant vehicle access.

Product Options

Mascot Engineering offers a wide product range to suit varied applications, with trench grates manufactured in accordance with Australian Standards:

-

- GMS Trench Grates and Frames: Galvanised mild steel, cost-effective and stocked in standard lengths and widths.

- GMS Heelproof Trench Grates and Frames: Safe option for pedestrian sites, suitable for public areas.

- Cast Iron Trench Grates and Frames: Heavy-duty strength for industrial projects, highways, and loading docks.

- Stainless Steel Grating: Corrosion-resistant choice for coastal or hygienic environments.

- DriveDrain System: Lightweight GRC trench system available in multiple widths for residential, commercial, and industrial projects. The drivetrain channel system can be supplied with a range of grating, including; stainless steel, GMS and cast iron – depending on the load rating requirements.

- Technodrain: Technodrain is a light weight polymer channel system that can be used in both light and heavy duty applications.

Installation and Maintenance Guidance

Correct installation is critical to ensure compliance to AS3996:2019, and ensure performance and the longevity of the product. Before installing Mascot Engineering trench grates, please see our installation instructions, or call our team on 1300 885 295.

Common Mistakes to Avoid

- Using a lower class than required, which may not withstand the expected vehicle loads.

- Incorrect alignment of frames, leading to uneven surfaces.

- Ordering insufficient stock quantities is causing delays to project timelines.

Maintenance Tips

- Regularly clean channels and grates to prevent blockages.

- Regularly check galvanised trench grates in high-moisture environments for signs of corrosion.

- Promptly replace any worn parts to maintain site performance.

Mascot Engineering also provides technical details, and ongoing advice on selecting trench grating, grate and frame, and installation. Please contact the team for further information.

Case Studies and Proven Applications

Mascot Engineering’s trench grates are installed in driveways, loading docks, carparks, and major infrastructure projects across Australia, demonstrating compliance with Australian Standards, durability under heavy use, and reliable long-term performance.

A great example of Mascot’s GMS Trench Grating in action can be seen in Transport for NSW’s rail upgrade at Erskineville in Sydney. Read the cast study here.

Trusted Supplier of Durable and Compliant Trench Grating

Selecting the right supplier is just as critical as choosing the correct trench grating. For over 100 years, Mascot Engineering has delivered high-quality products to suit projects of every scale across Australia.

Here’s why specifiers, plumbers, councils and builders rely on Mascot:

- Specialists in galvanised trench grates, stainless steel grating, cast iron grating and a range of channel system options.

- Standard lengths and widths are supplied in stock, with custom options available.

- Products are manufactured to comply with AS3996, ISO and local council requirements.

- Proven performance across driveways, loading docks, carparks and major infrastructure works.

- Local expertise providing technical details and project-specific advice.

From residential sites to heavy-duty industrial projects, Mascot’s trench grates combine compliance, durability and cost efficiency, giving installers confidence in every project.

FAQs

Q1. What is trench grating?

Trench grating is a surface drainage system whereby grating is seated into a frame above a drainage channel that receives surface water and delivers that water to the municipal stormwater drainage system, preventing flooding and keeping sites safe for vehicles and pedestrians.

Q2. Where is trench grating used?

Trench grating is used in driveways, carparks, shopping centres, loading docks and industrial sites to manage surface water, protect infrastructure and improve safety for vehicles and pedestrians.

Q3. What are the load classes for trench grating?

Mascot Engineering trench grating is manufactured to comply with AS3996:2019 load ratings: Class A for pedestrian traffic areas, including paths, Class B for driveways and carparks, Class D for industrial and loading dock applications, and Class G for heavy duty infrastructure projects such as airports and ports.

Q5. What are galvanised trench grates best suited for?

Galvanised trench grates are a good choice for general purposes such as residential driveways, carparks and commercial applications. They are cost-effective, durable, and readily available, and are compliant with Australian Standards.

Q6. What are the standard lengths available for trench grates?

Standard lengths include 1000 mm grate sections and 2000 mm frame lengths for trench grate and frame products. Channel drainage products are available as a complete unit in 1000 mm lengths and a variety of widths. These are supplied in stock for common applications, with custom lengths available to suit specific project requirements.

Q7. What standards do Mascot trench grates comply with?

Mascot trench grates are manufactured to AS3996, produced under ISO-certified processes, and designed to meet local council requirements. This ensures durability, compliance, and performance across residential, commercial, and industrial projects.